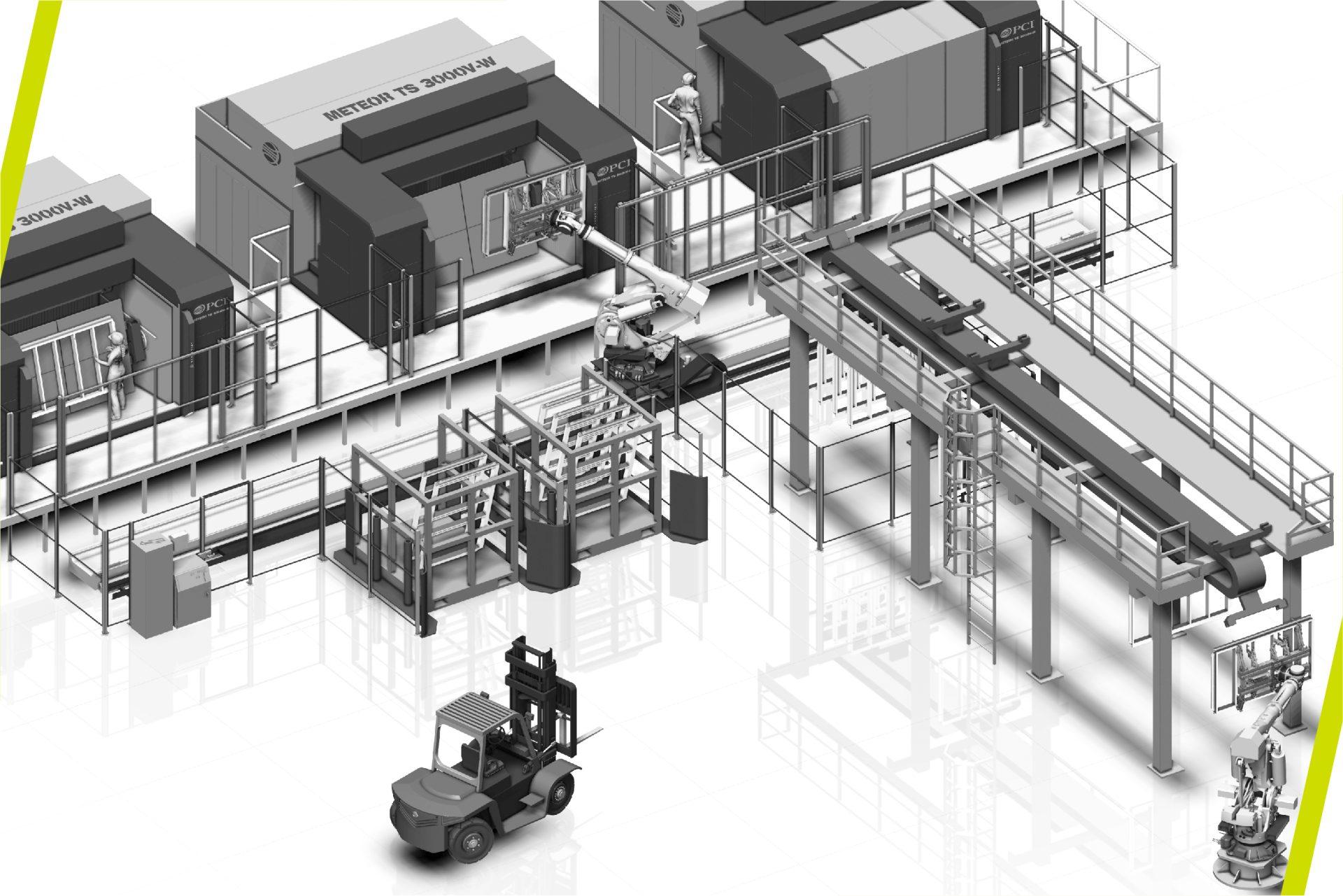

End-to-end industrial solutions, from machines to services

Industrial solutions designed as a whole

At PCI, we design tailor-made production solutions where every component (machine tool, automation, process, supervision, and services) is fully integrated into a coherent, robust, and scalable industrial system.

Our approach is built on three complementary areas of expertise: machining, automation, and 360° services.

They come together through a single point of contact, clear project management, and a shared commitment: helping you produce with complete peace of mind.

Our combined expertise

Tailor-made machining

Machining solutions tailored to your parts, your production rates, and your quality requirements.

Automation & Robotics

Optimize your workflows and secure your operations with custom robotic solutions.

Retrofit & Retooling

Modernize your equipment, extend its lifespan

360° Services

End-to-end support, from feasibility study to equipment upgrades.